Airsafe® medical aerosol high-flow suction systemshave been designed in 2020 in response to the need to decrease risk of exposure for healthcare operators.

The constant increase of hospital admissions required a further effort to healthcare facilities, for which it is a necessity to put together personal protective equipments (PPE as masks, gloves, visors, scrubs, etc.) already supplied by clinics, with active protection systems to ensure a safer work-environment for operators.

As a fact, PPE are passive protections against biohazard. This means PPE screen respiratory tracts to avoid contamination, standing between respiratory tracts and contaminants. The only way to be sure to abate infection risks is to upgrade to an active solution: capable to catch infected aerosol before it pollutes the room and so before it has the chance to reach PPE and operators’ respiratory tracts, exactly as it happens in industrial contexts to protect workers from steam and dust.

Among procedures at greater risk of contamination, there are not only interventions in the operating rooms, but also basic moves, which doctors and nurses do every day:

- strep throat (oropharyngeal/nasopharyngeal)

- endotracheal intubation

- non-invasive ventilation

- tracheotomy

- manual ventilation

- extubation

- bronchoscopy

- sputum collecting

- high-flow oxygen delivery

- aerosol therapy delivery

These everyday situations really show Airsafe® medical aerosol high-flow suction systemsuselfulness. Operators involved in this type of care is particularly exposed, but they can also be potential vehicle of infection. The transmission happens via respiratory secretions inhalables from others through nose, mouth and eyes, since healthcare operators take care of a high number of patients in the same room and in very short time, in case they are the vehicle, number of people in danger increases rapidly.

User-friendly in every operations

Each component of Airsafe® machineries and plants is designed to support healthcare operators’ work, with no interference in their operations:

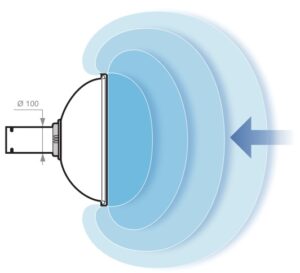

- High-flow capacity and circular hood create a half-sphere of negative pressure with large diameter, within which air and particles are aspired to abate contaminant straight from the source at a distance of 20/30cm from the patient.

|  |

- Clear hood and arm with junctionsto place the aspirator conveniently, with no interference in operators’ moves and vision.

| |

- Airsafe® filtration stages are certified with final grade H14 or U15, depending on machinery models. Those arelevels of absolute filtration,capable to grant abatement of airborne particles up to 99.9995%, already employed in hospitals’ air conditioning plants. Airsafe® makes all this even safer, thanks to a patented pre-separation stage of wet parts, which enables operators to clean machinery simply spraying standard sanitizing products in the suction hood.

| |

The right Airsafe® system for each facility:

- Mobile medical aerosol suction system with self-supporting arm

- Wall- or ceiling-mounted medical aerosol suction system

- Centralized medical aerosol suction plant

Find out the best solution for you supported by our Technical Dept.